|

|

|||||

| Home | |||||

| Team members | |||||

| Project abstract | |||||

| Objectives | |||||

| Dissemination | |||||

|

|||||

| Contact |

Stage 2022: ![]()

Objectives:

Stage 3/2021: Accelerated UV aging correlated with flame resistance capacity of the semi–interpenetrating polymer networks (S–IPNs).

Activity 3.1. Photochemical behavior study of the obtained S–IPNs

Activity 3.2. Promoting the project visibility

Activity 3.3. Dissemination of the results obtained throughout the entire project implementation

Final Scientific Report - 2022: ![]()

Stage 2022 Summary

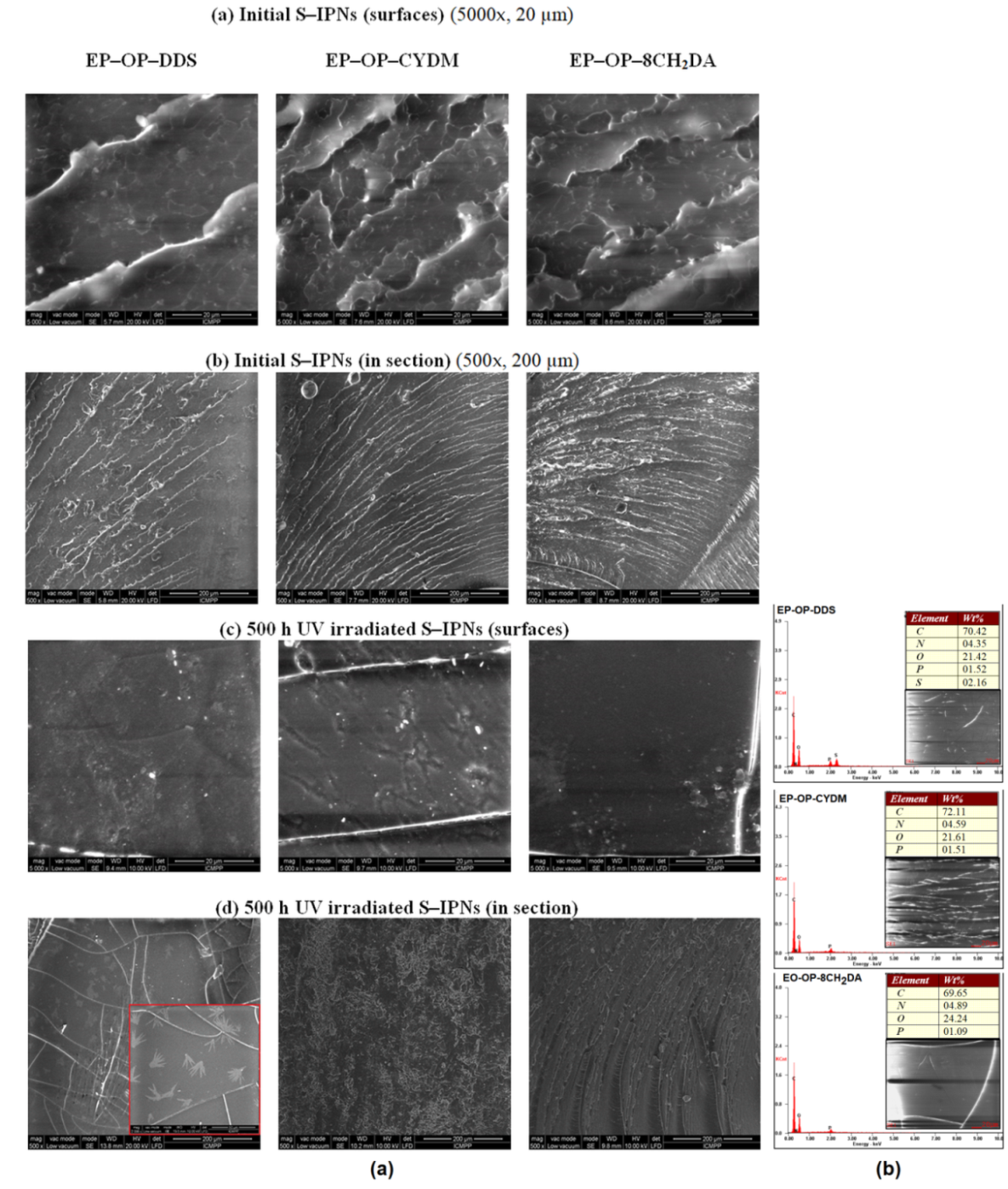

The networks exhibited color modifications and structural degradation during UV exposure. This aspect was reflected in morphological and structural modifications. The aggressive action of the UV irradiation generates visible cracks on the surfaces of the samples and a series of irregular shapes, which seem to appear on both the surface and into the mass of the materials, underneath the physically observable cracks. The section SEM micrographs of the S–IPNs also indicate discontinuities, and cracks into their linear and relatively uniform aspect. The EP–OP–DDS S–IPN exhibits a ‘sea–island’ morphology type of a hand–like shape after UV irradiation. The EDX profiles of the photoirradiated S–IPNs show lower carbon, nitrogen and relatively the same phosphorus contents and higher oxygen percentage, due to photo-oxidation as compared to those of the initial S–IPNs reported in Stage 2. Only the EP–OP–8CH2DA S–IPN shows slightly lower oxygen content after photodegradation, due to more advanced decomposition of hydroperoxide intermediates.

The variation of the color parameters show a general darkening tendency of the S-IPNs surfaces during UV irradiation, due to accumulation of instable red and yellow chromophores.

The UV–Vis reflectance spectra of the S–IPNs show significant decreases in reflectance in the visible domain (400–800 nm) for all samples after 500 h of UV irradiation. The decrease of reflectance value could be correlated with a higher sensitivity of the samples to photodegradation, due to increase of light absorbance capacity.

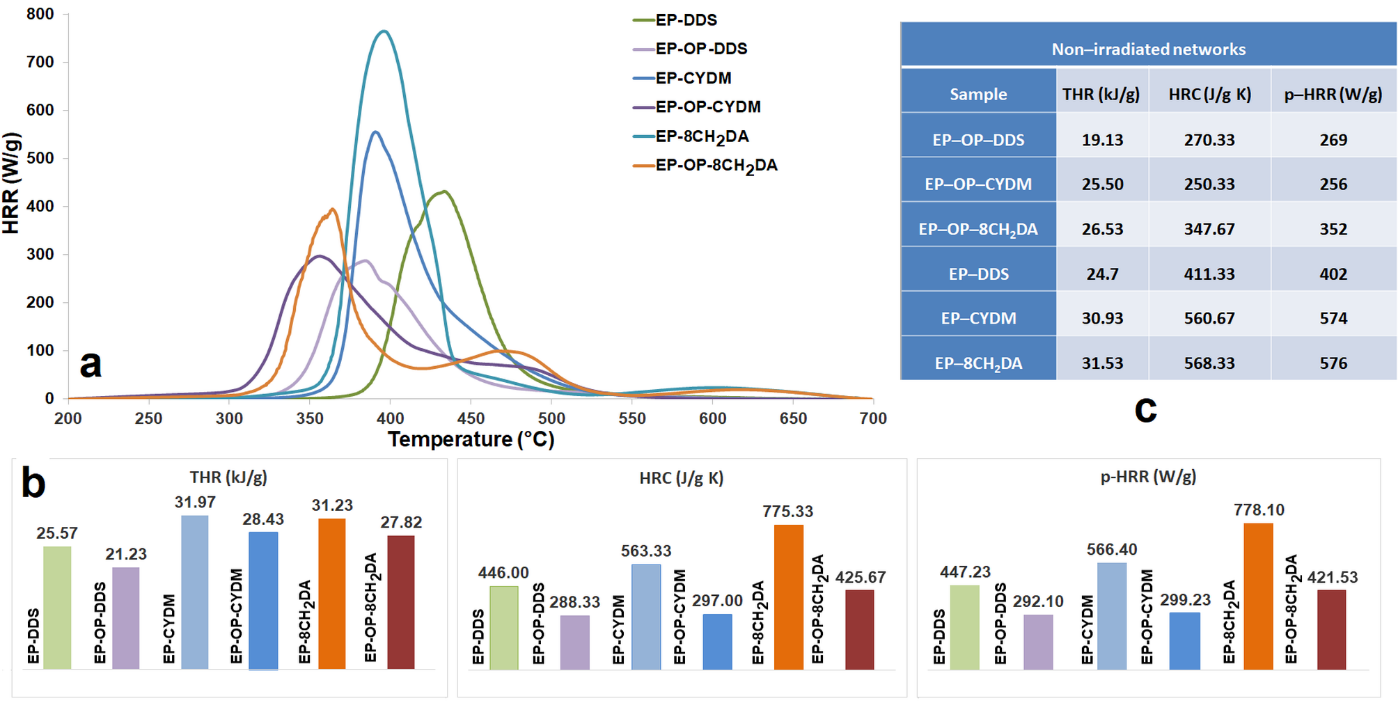

The flame resistant capacity measurement results of the photo-irradiated S–IPNs were compared to those of the initial S–IPNs, reported in Stage 2 of the project. In Stage 2 of the project it was reported that the p–HRR values decrease with 55.4% (EP–OP–CYDM vs. EP–CYDM), 38.9% (EP–OP–8CH2DA vs. EP–8CH2DA) and 33.08% (EP–OP–DDS vs. EP–DDS). UV irradiation leads to a decline in the fire performance of the S–IPNs. This is reflected through the seemingly increased MCC parameters of the irradiated S–IPNs compared to the ones of the initial samples, especially the HRC and p–HRR values. The data indicate that the exposure to UV light has a damaging effect on the S–IPNs through polymer chain scissions.

• An overall significant aspect is that, although a surface phenomenon, UV irradiation contributes to decreasing the flame retardant capacity of the S–IPNs, hence affecting the bulk of the materials.

• In the present phase of research, the S–IPNs are not yet recommended for outdoor light exposure. It is therefore that the conducted research to this point constitutes a valuable basis towards finding suitable photostabilizers for the S–IPNs in the future.

| Designed & Maintained by CLICK NET SOLUTIONS |